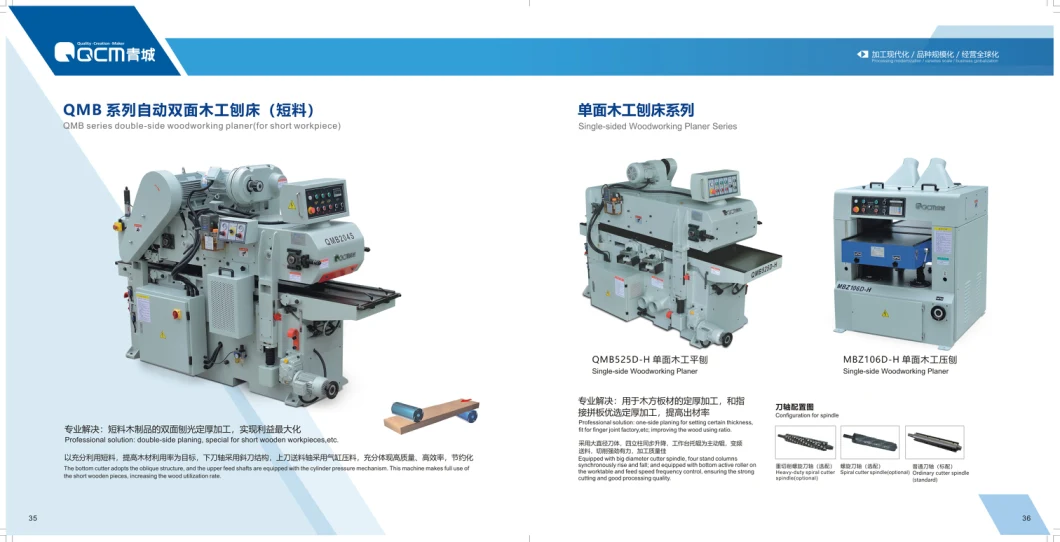

2-side Planer/Double Side Planer/Woodworking planer Woodworking Machinery for Solid wood/wooden Furniture

QMB206F-K/F-H Double side planer Thicknesser planer

Excellent features:

1. The machine adopts whole casting body, aging treatment, stable performance;

2.The working table adopts special wear-resisting material, which has enough rigidity and wear resistance;

3. The cutter shaft is precision machined, dynamically balanced and precision assembled, with smooth running and good precision;

4.Feeding material adopts elastic pressure claw, with adjustable strength, smooth feeding and good quality of processed board surface;

5. The upper and lower drive rollers are adopted in the upper pressure planing system, which makes the material feeding strong and powerful;

6. The feeding system adopts frequency conversion speed control (F series is stepless transmission) to ensure the quality of different wood products;

7. The lifting system adopts digital display, intuitive and convenient operation;

All electrical components and transmission parts are of good brand and components, stable performance;

9.Quick belt tension adjustment and quick planer replacement, convenient operation;

10.630 series is equipped with manual lubrication pump to lubricate the column sliding plate to ensure the flexibility of lifting;

11.K-type products are equipped with numerical control automatic thickness gauge, which is accurate in thickness setting and convenient in operation.

Qingcheng Machinery Co.,LTD established in 1970 which are speclializing in producing all kinds of woodworking machines, like Four Side Moulder, Double Side Planer, Automatic Muti-blade Rip Saw, Automatic Single-side Rip Saw and Double-end Tenoning Machine, Wood Planer etc.

It's been 50 years since we have devoted our-self to the development and manufacturing of woodworking machinery. During the last 50 years, we developed:

1. Our own casting foundry which can meet the demand of annual output of 15000 tons of large castings.

All the machines is cast in one piece which has advantage of high precision, high stablity.

2.Siemens electronic components for all the machines, well-organized and good stability.

3.A complete and advanced processing mother-machines lines which costs 3 million dollars imported from Japan. High precision mother machines produce final machines with high precision, within tolerance +-0.1S.

Those advanced equipment insure you precision, performance and durability, with mass production in big quantity. So that we can insure our customers fast delivery time, high quality and perfect performance.

FAQ

Below FAQ for your reference, if you have any further questions, we are always here for you.

1, Manufacturer or Trading company?

Yes, we are professional machine producer since 1970.During the last 50 years, we devoted our-self to the development and manufacturing of woodworking machinery with passion and innovation. You will be always welcomed to visit our factory.

2, What's your payment term?

30% deposit and 70% balance should be paid before delivery.

3, How about your after-sale service?

Our engineers are available to service overseas to provide professional technical support.

4, Warranty of double side planer?

Its warranty is 12 months.

5, What's your leading time of thicknessing machines?

Within 2 days for regular stocked machine after receiving deposit.

2 months for OEM machines.

7, What's your delivery term of planer thicknesser?

---FOB shanghai/Ningbo

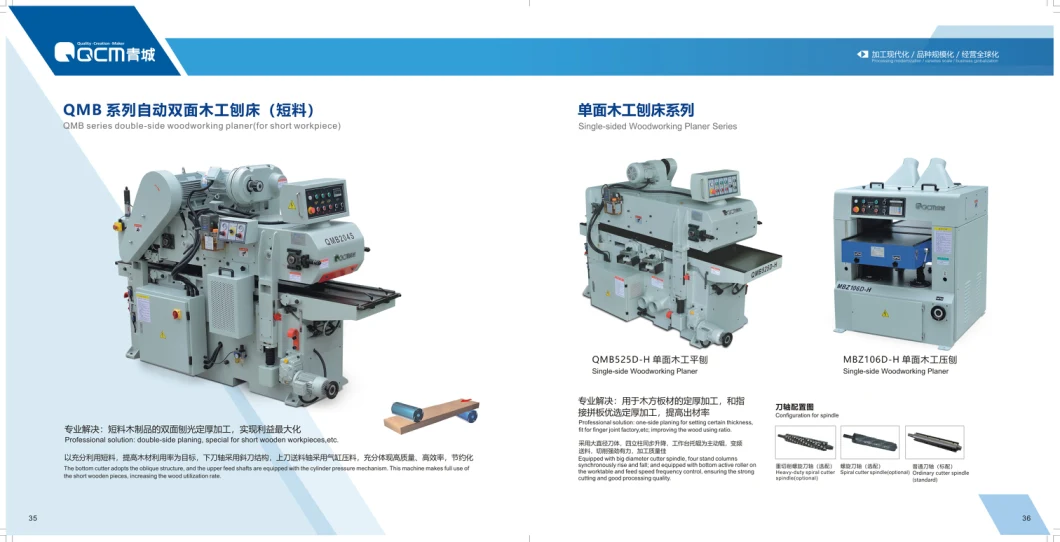

QMB206F-K/F-H Double side planer Thicknesser planer

Excellent features:

1. The machine adopts whole casting body, aging treatment, stable performance;

2.The working table adopts special wear-resisting material, which has enough rigidity and wear resistance;

3. The cutter shaft is precision machined, dynamically balanced and precision assembled, with smooth running and good precision;

4.Feeding material adopts elastic pressure claw, with adjustable strength, smooth feeding and good quality of processed board surface;

5. The upper and lower drive rollers are adopted in the upper pressure planing system, which makes the material feeding strong and powerful;

6. The feeding system adopts frequency conversion speed control (F series is stepless transmission) to ensure the quality of different wood products;

7. The lifting system adopts digital display, intuitive and convenient operation;

All electrical components and transmission parts are of good brand and components, stable performance;

9.Quick belt tension adjustment and quick planer replacement, convenient operation;

10.630 series is equipped with manual lubrication pump to lubricate the column sliding plate to ensure the flexibility of lifting;

11.K-type products are equipped with numerical control automatic thickness gauge, which is accurate in thickness setting and convenient in operation.

| Specifications | Unit | QMB206F-K/F-H |

| Working width | mm | 630 |

| Working thickness | mm | 10-170 |

| Min.working length | mm | 310 |

| Max cutting depth(Upper and Bottom) | mm | 5\3 |

| Feeding speed | m/min | 5.3-20 |

| spindle speed | r/min | 4800 |

| spindle cutting dia | mm | Φ125 |

| Total power | kW/HP | 22.25/30 |

| Spindle motor | kW/HP | / |

| Top Spindle motor | kW/HP | 11\15 |

| Bottom Spindle motor | kW/HP | 7.5/10 |

| Front blade spidle motor | kW/HP | / |

| Back blade spidle motor | kW/HP | / |

| Feeding motor | kW/HP | 3\4 |

| Lifting motor | kW/HP | 0.75/1 |

| Suction hood dia | mm | 4*Φ150 |

| Overall dimensions | mm | 2900X1180X1830 |

| Weight | kg | 3200 |

Qingcheng Machinery Co.,LTD established in 1970 which are speclializing in producing all kinds of woodworking machines, like Four Side Moulder, Double Side Planer, Automatic Muti-blade Rip Saw, Automatic Single-side Rip Saw and Double-end Tenoning Machine, Wood Planer etc.

It's been 50 years since we have devoted our-self to the development and manufacturing of woodworking machinery. During the last 50 years, we developed:

1. Our own casting foundry which can meet the demand of annual output of 15000 tons of large castings.

All the machines is cast in one piece which has advantage of high precision, high stablity.

2.Siemens electronic components for all the machines, well-organized and good stability.

3.A complete and advanced processing mother-machines lines which costs 3 million dollars imported from Japan. High precision mother machines produce final machines with high precision, within tolerance +-0.1S.

- Japan's OKUMA five-surface gantry machining-center

- Japan's LGMazak FMS flexible machining production line

- MAKINO horizontal machining center

- MORI SEIKI(nine-axis linkage) lathe-mill cutting center

- LGMazak vertical machining center

- Japan's Mitsubishi laser cutting machine

- Japan's OKK large machining center

- Japan's Okamoto CNC grinding center

- Japan's Mitutoyo three coordinate measuring machine.

Those advanced equipment insure you precision, performance and durability, with mass production in big quantity. So that we can insure our customers fast delivery time, high quality and perfect performance.

FAQ

Below FAQ for your reference, if you have any further questions, we are always here for you.

1, Manufacturer or Trading company?

Yes, we are professional machine producer since 1970.During the last 50 years, we devoted our-self to the development and manufacturing of woodworking machinery with passion and innovation. You will be always welcomed to visit our factory.

2, What's your payment term?

30% deposit and 70% balance should be paid before delivery.

3, How about your after-sale service?

Our engineers are available to service overseas to provide professional technical support.

4, Warranty of double side planer?

Its warranty is 12 months.

5, What's your leading time of thicknessing machines?

Within 2 days for regular stocked machine after receiving deposit.

2 months for OEM machines.

7, What's your delivery term of planer thicknesser?

---FOB shanghai/Ningbo