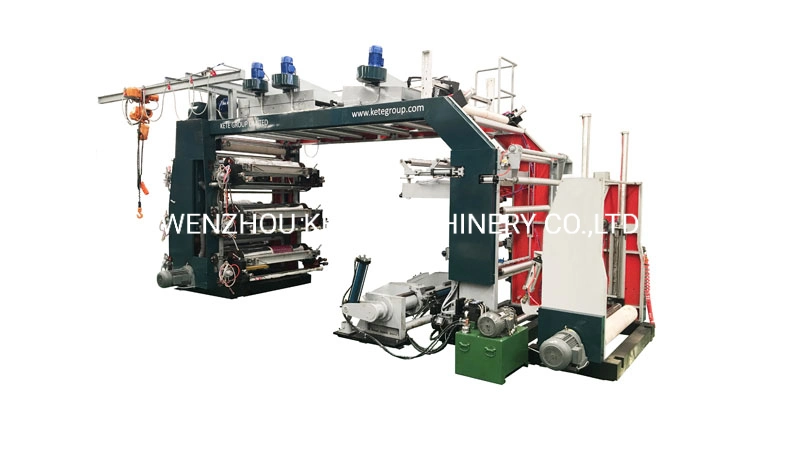

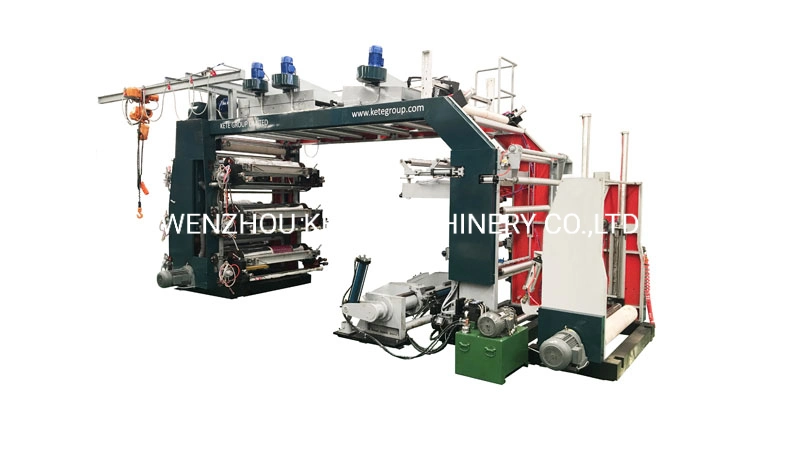

Stack Type Flexo Printer Printing Machine, Flexography Printing Machine, Flexografic Printing Machine, Flexo Graphic Printing Machine

Main Machine Specification:

Feature:

- Unwinding use auto tension control, use 5kg magnetic power brake.

- Rewinding use auto tension control, use 10kg magnetic power brake.

- Unwinding have EPC System and auto tension control

- The whole machine is use PLC Control system.

- Ceramic Anilox Roller 250LPI, 400 LPI, 600 LPI(or decide by customer)

- Use Taiwan brand blowing fan.

- Main motor use Taiwan brand, with Panasonic inverter. Use Taiwan brand auto counting system

- Most electrical part use Taiwan brand or Korea brand, bearing use Japan brand

- Roller all use Oxidation treatment, Static balance and dynamic balance treatment

- Use closed type doctor blade system

- Ink recycle system

Main Machine Specification:

| Model | KTFP-B81000 |

| Printing Color | 8 Color |

| Printing Width | 1000mm |

| Printing Length | 190-890mm |

| Printing Speed | 80-150m/min |

| Ceramic Anilox Cylinder | 250~600LPI JAPAN |

| Register precision | Longitude ±0.25mm Transverse ±0.25mm |

| Diameter of Unwind | 600mm |

| Diameter of Rewind | 600mm |

| Tension Range | 3-50kg |

| Tension precision | ±0.3kg |

| Paper core of unwind & rewind | Φ76mm (inner diameter) |

| Unwind and rewind material holder | Air shaft |

| Air supply | 0.6mpa |

| Press power | Mechanic control |

| Doctor blade | Double sided Enclosed type |

| Inking | Auto cyclic system |

| Inking distributing | Deceleration motor (reduction ratio 1 : 50) |

| Drying model | Electrical Drying |

| Drying power | 34KW |

| Air blower (large) | 1.1kw / 2 pcs |

| Air blower (small) | 750w / 4 pcs |

| Master motor power | 3.7(reduction ratio 1 : 5) |

| Machine power | 20KW |

| Machine size | 5.0m × 2.2m × 3.2m |

| Deviation correction system | Auto hydraulic pressure |

| Printing plate lifting system | Auto hydraulic pressure |

| Unidirectional bearing | Germany |

| Frequency conversion controller | Japan |

| Power: | 380Voltage,3phase and 50HZ |