Woodworking PVC Edge Banding Machine for Panel Furniture Processing

What is the details of our edge banding machine?

1. Glue pot is casted as a whole part. So it won't broken.

2. Glue shaft is patent design, CNC processing, to guarantee the glue output and daub evenly.

3. All edge banding parts adopt CNC processing, error control within 0.017 mm.

4. End cutting tidily, docking closely between the cutting end, basically no gap.

5. Our bearings are made in Japan.

Pneumatic element: Airtac from Taiwan

Electric device: Omron (Japan), TECO (Taiwan), Schneider (France)

Motor: TUNGLEE (Taiwan) High-frequency motor from Japan

Product Description

| Type | R5A |

| Banding tape thickness | 0.4-3 mm |

| Banding tape width | 12-65 mm |

| Work piece thickness | 10-60 mm |

| Work piece length | >=100 mm |

| Work piece width | >=50 mm |

| Heating power | 1.8 KW |

| Feeding motor power | 3.7 KW |

| Glue spreading power | 0.75 KW |

| End trimming power | 0.5 KW x 2 |

| Rough trimming motor power | 0.75 KW x 2 |

| Fine trimming power | 0.75 KW x 2 |

| Corner rounding motor power | 0.5 KW x 2 |

| Polishing motor power | 0.37 KW x 2 |

| Feeding speed | 10-23 m/min |

| Air pressure | 0.8 Mpa |

| Overall dimension | 5670x850x1520 mm |

| Packing size | 5700x880x1580 mm |

| N.W. | 2300 KGS |

| G.W. | 2450 KGS |

Feature:

1.The glue mechanism adopts a special structure to gelatinize the plates and costing materials uniformly, ensure a more solid conglutination.

2.End trimming mechanism through a precise guide track movement; adopt automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

3.Rough/fine trimming mechanism is used for repairing the excess edge materials, adopt automatic tracking and high frequency motor fast cutting structure to ensure the trimming plates smoothly.

4.Profiling unit is to make the board ending more smooth and aesthetic

5Scraping unit is for a perfect finishing of the applied edge.

6.The buffing device adopts the board processed by cotton polishing wheel, by end polishing to make a more smooth surface.

What is the functions of our sliding table saw?

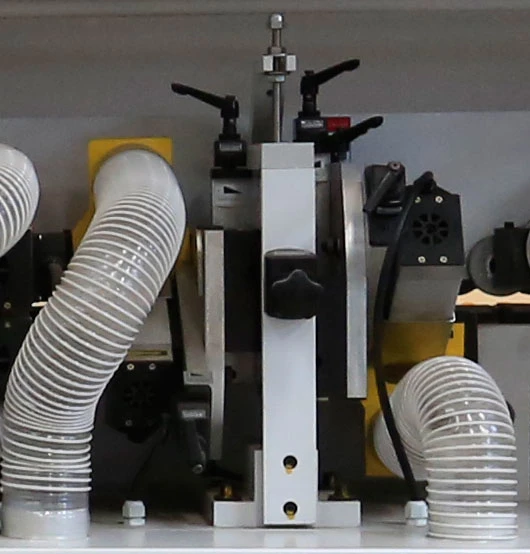

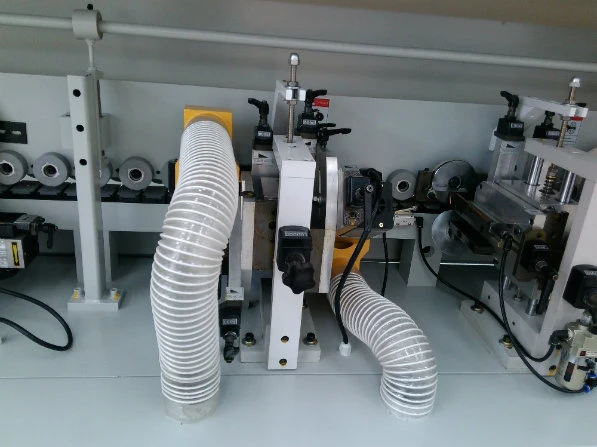

Pre-milling

Gluing

End cutting

Rough Trimming

Fine Trimming

Scraping & Buffing

Qingdao Zhongding Machinery Co., Ltd is a leading company of specializing in manufacturing and exporting woodworking machine, and we are able to offer professional woodworking machines to customers. Our company has professional technology, full range of testing lines and pipelining, and four professional production lines of woodworking machine. It is located by the beachside of the Yellow sea, which is a place of strong competitive power, beautiful natural environment, and easy traffic of air, land and sea transportation.