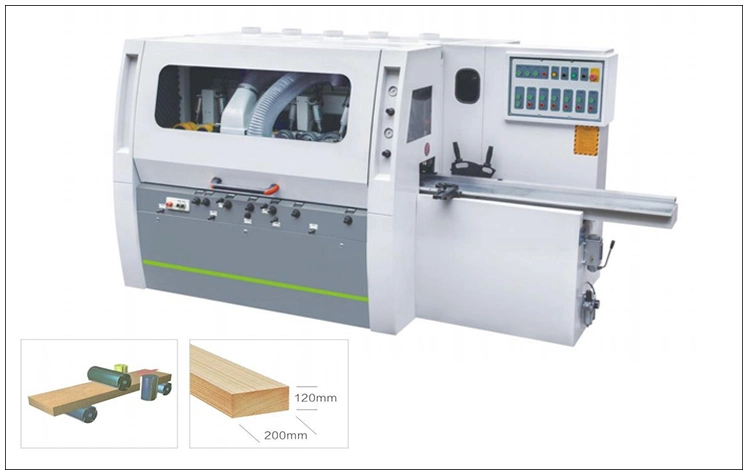

Factory Price Woodworking Four-Sided Planer Moulder Machine

Description

Working Width | 25-200mm |

Working Thickness | 8-120mm |

Operating Platform Length | 1800mm |

Feeding Speed | 5-38m/Min |

Spindle Diameter | 40mm |

Spindle Speed | 6000r/Min |

Gas Source Pressure | 0.6mpa |

First Bottom Spindle | 5.5kw/7.5hp |

First Top Spindle | 7.5kw/10hp |

Right Side Spindle | 5.5kw/7.5hp |

Left Side Spindle | 5.5kw/7.5hp |

Feed Beam Rise&Fal | 0.75kw/1hp |

Feeding | 4kw/5.5hp |

Total Motor Power | 28.75kw |

Right Side Spindle | 125-180mm |

Left Side Spindle | 125-180mm |

First Bottom Spindle | 125mm |

Second Top Spindle | 125-180mm |

Feeding Wheel Diameter | 140mm |

Dust Absorption Tube Diameter | 140mm |

Overall Dimensions | 3370*1600*1700mm |

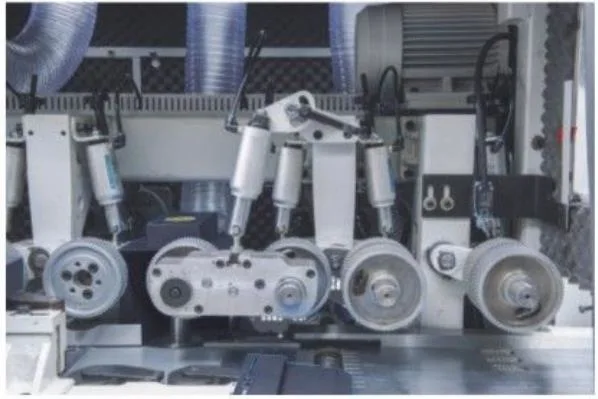

HC-M420 Four Side Moulder Machine1.The spindle uses the independent operation,shearing force is

strong.

2.Adopting frequency control,feeding speed reaches 5-30 meters.

3.The spindle can be up and down and move around to facilitate the various shapes processing of wood line.

4.The plating workbench is smooth and wearable.

5.Spindle adjustment concentrated in the front,easy to operate.

6.Equipped with a short feeding device,it is effectively to improve the utilization of short-material processing.

7.Workstations equipped with under active rollers to ensure smooth feeding.

8.Fully enclosed protective cover to avoid sawdust flying and noise isolation,it plays a role in security protection.

9.Pneumatic pressure feed wheel which can divide adjustment pressure,it is advantageous in the adjustment pressure of different

thickness wood to ensure smooth feeding.

|  |

| Up&down active feeding wheel,ensure feeding smoothly. | Short feeding device,ensure short material processing and feeding smoothly. |