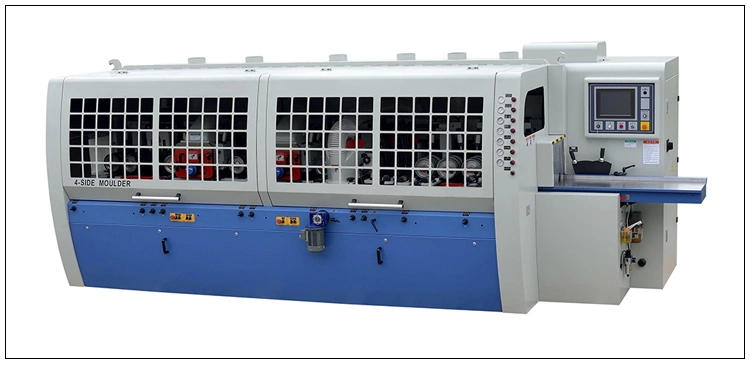

6 Spindle Four Side Woodworking Planer Moulder For Sale

Product Description

| Model | HC633H-D |

| Working Width | 50-330mm |

| Working Thickness | 20-250mm |

| Min. Working Length | 700/300mm |

| (Intermittent/Continuous) | |

| Feeding Speed | 8-36m/min |

| Spindle Diameter | 50mm |

| Rotation speed of spindle | 6000r/min |

| Cutter Dia.First Bottom Cutter | 140mm |

| Left/Right Vertical Cutter | 140-230mm |

| The First Upper Cutter | 140-230mm |

| Back Bottom Cuter | 140-230mm |

| Total Power | 84kw |

| The First Bottom Cutter | 11kw |

| Left Vertical Cutter | 11kw |

| Right Vertical Cutter | 11kw |

| The First Upper Cutter | 15kw |

| The Second upper Cutter | 11kw |

| The Second Bottom Cutter | 11kw |

| Feeding Motor | 11kw |

| Beam Lifting Power | 1.5kw |

| Upper cutter lifting motor | 0.75kw |

| Radial adjustment of the vertical spindle | 0.37kw |

| Rear pressing plate elevation | 0.37kw |

| Suction hood dia. | 6*180mm |

| Air Supply Pressure | 0.6mpa |

| Overall Dimensions | 6000*2280*2090mm |

| Weight | 9600kg |

Product Features:

1. The machine tool adopts casting body and is equipped with high-power motor to realize heavy cutting and good cutting quality;

2, the use of fully enclosed safety shields and open the door to power off, low noise, safety and environmental protection;

3, the active workbench and the front workbench plate fitting gold plate is hardened, wear resistance;

4. The main shaft adopts heavy cutting structure and the diameter of the main shaft is φ50mm, and the main shaft has good rigidity, which can achieve strong cutting;

5. Feeding with φ140 feeding wheel and multiple sets of lower driving roller, the feeding is powerful and powerful;

6. The control of each tool axis and the fixed width and thickness of the workpiece are all controlled by PLC computer touch screen CNC system. The cylinder is locked and easy to operate;

7. Feeding adopts the front, middle and rear three cylinders to press the material, the pressure is stable and the adjustment is convenient;

8. The front pressure before the upper knife and the side pressure mechanism of the vertical knife are all made of cylinder pressure, which is stable in pressure and convenient to adjust;

9. The second lower knife has a multi-slice saw function, which can perform multi-chip sawing processing;

10. Two manual lubrication pumps are configured to separately supply oil to the worktable and the moving rail to improve the smoothness of feeding and the flexibility of the guide rail.

11. All feeding and pressing materials adopt segmented cylinder pressing materials, centralized arrangement and convenient operation;

12. The feeding adopts frequency conversion speed regulation, and the feeding speed can reach 6-36m/min;

13. All electrical components and transmission parts are made of excellent brands and components with stable performance.

Sample

Package

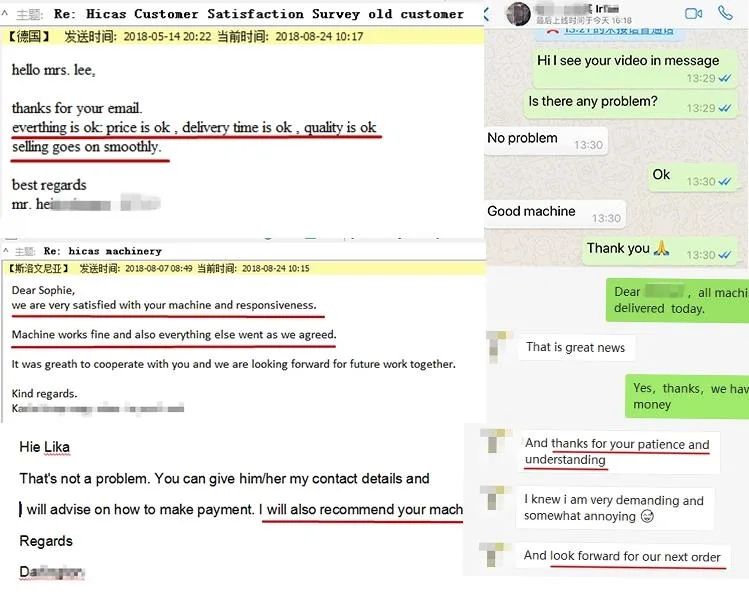

Why Choose Us

1. We have our own woodworking machinery factory.

2. As a professional manufacturer, we have 14 years factory experience for woodworking machinery.

3.Our products are widely sold in made-in-china.

4. More and more customers in the world are using our machine, we received many good feedbacks from lots of countries.

5.We have perfect after-sales service.

a. Machine guarantees 12 months.(The host machine warranty for one year, the wearing parts is no guarantee, but support will be provided)

b. 24 hours technical service by email or calling.

c. English manual and operation video.

d. Engineers available to service machine overseas, also welcome to our factory to learn the installation and use of the machines.

e. Regularly follow-up by email or cellphone

f. Expanding your production or upgrading machine in the future, professional solution will be provided.

6. We are looking for Good customers like you! and Distributor or Agents Wanted!!!

Learn more about us on SNS